Shenzhen Prechem New Materials Co., Ltd.

Comparative Application Testing of EEP and PMA in 2K PU Black System

Experimental Purpose and Conditions

Apply the new solvent EEP and the traditional solvent PMA respectively in a 2K PU black system. Compare the performance differences generated by the two in the 2K PU black system by analyzing the results of a series of tests.

Test Conditions: Temperature 25-27°C, Humidity 50-60%.

Test Basis: Refer to QC/T 484-1999 Automotive Paint Coating Standard.

Experiment and Data Analysis

1. Black Paint Preparation:

Technical Parameters of Main Raw Materials:

| Name | Apariencia | Punto de inflamación | Purity | Punto de ebullición | Viscosity 25°C, mPa.s |

| EEP (3-Ethoxyethyl Propionate) | Colorless transparent | 59°C | ≥99% | 169°C | 1.3 |

| PMA (Propylene Glycol Monomethyl Ether Acetate) | Colorless transparent | 42°C | ≥99% | 145°C-146°C | 1.6-2.5 |

Black Paint Main Agent Formula (A1 & A2):

| No. | Material | Amount A1 | Amount A2 | Supplier | Production Process |

| 1 | SM 516/70BAC Hydroxypropyl Resin | 85.5 | 85.5 | Cytec | Add ingredients in order, disperse at medium speed (500 rpm) for 5 minutes. |

| 2 | EEP | 4.5 | – | PREC | |

| 3 | PMA | – | 4.5 | Commercial | |

| 4 | 9007-U Black Paste | 10 | 10 | Cody | |

| Total | 100 | 100 |

Coating Curing Agent B Formula:

| No. | Material | Amount | Supplier |

| 1 | HT-100 Curing Agent | 30 | Wanhua |

| 2 | Butyl Acetate | 20 | Commercial |

Thinner Formula (C1 & C2):

| No. | Material | Amount C1 | Amount C2 | Supplier |

| 1 | Butyl Acetate | 90 | 90 | Commercial |

| 2 | EEP | 10 | – | PREC |

| 3 | PMA | – | 10 | Commercial |

Coating Ratio:

- 2K PU Black (EEP) Ratio Main Agent A1 : Curing Agent B : Thinner C1 = 2 : 1 : 0.7

- 2K PU Black (PMA) Ratio Main Agent A2 : Curing Agent B : Thinner C2 = 2 : 1 : 0.7

2. Test Results and Analysis

Basic Performance:

| No. | Test Items | Test Standards | Requirement | Test Results | |

| 2K PU Black (EEP) | 2K PU Black (PMA) | ||||

| 1 | Liquid Coating Odor | – | As tested | Medium-low ether-ester odor | Medium ether-ester odor |

| 2 | Surface dry, h | GB/T 1728-1979 | ≤2 | 90 minutes | 90 minutes |

| Hard dry, h | ≤24 | 12 h | 12 h | ||

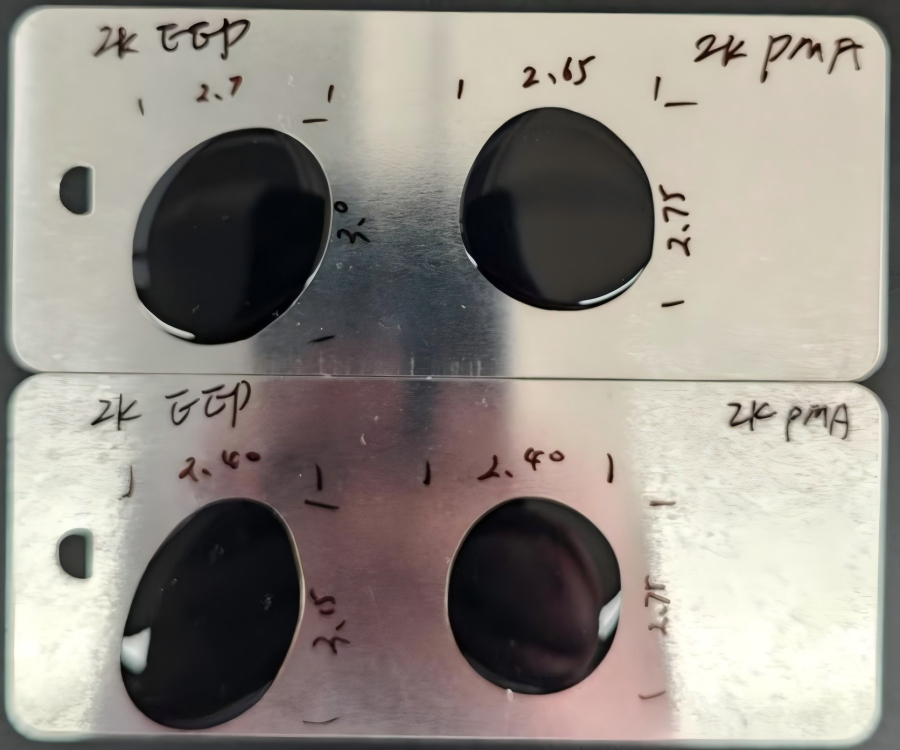

| 3 | Flowability 1 | – | As tested | Left/Right: 2.70cm Up/Down: 3.00cm | Left/Right: 2.65cm Up/Down: 2.75cm |

| Flowability 2 | – | As tested | Left/Right: 2.40cm Up/Down: 3.15cm | Left/Right: 2.40cm Up/Down: 2.75cm | |

| |||||

| 4 | Film Appearance | – | Visual Inspection | Normal | Normal |

| 5 | Thickness (Flow Coating), μm | – | As tested | 36.1 | 40.3 |

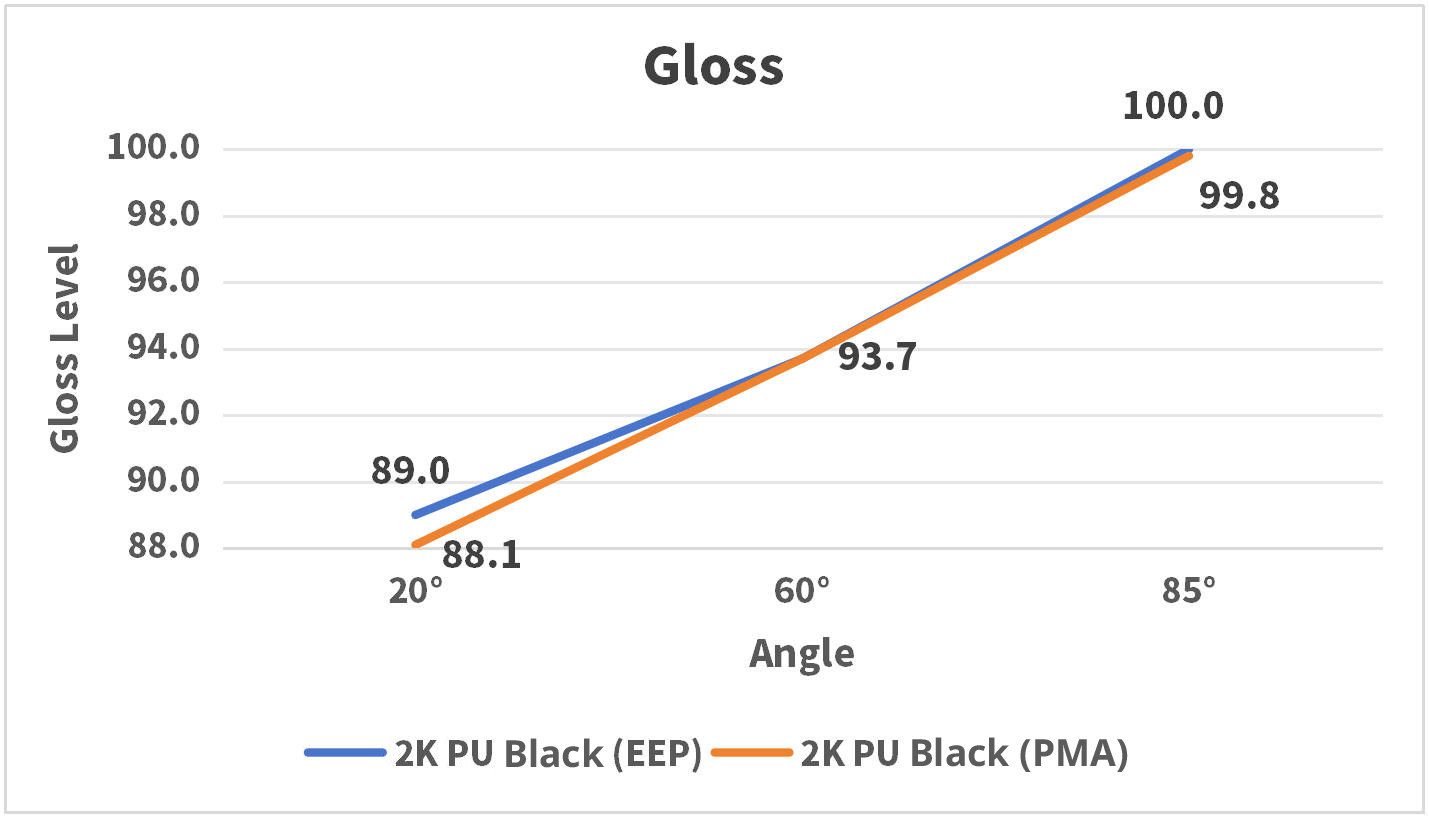

| 6 | Gloss 20°/60°/85° angle | GB/T 9754-2007 | As tested | 89.0/93.7/100.0 | 88.1/93.7/99.8 |

| |||||

| 7 | Pencil Hardness (Scratch – Zhonghua) | GB/T 6739-2006 | As tested | H | H |

| 8 | Cross-Cut Test, grade | GB/T 9286-1998 | ≤1 | 1 | 1 |

| 9 | Impact Resistance, cm (Direct/Reverse) | GB/T 1732-1993 | 50/50 | No crack/No crack | No crack/No crack |

| 10 | MEK Rub Resistance | – | 100 cycles | No change | No change |

Application Performance:

| No. | Test Items | Test Standards | Requirement | Test Results | |

| 2K PU Black (EEP) | 2K PU Black (PMA) | ||||

| 1 | Film Thickness, μm | Spray, stand 5 min, bake 80°C * 1 h | As tested | 48.8 | 48.7 |

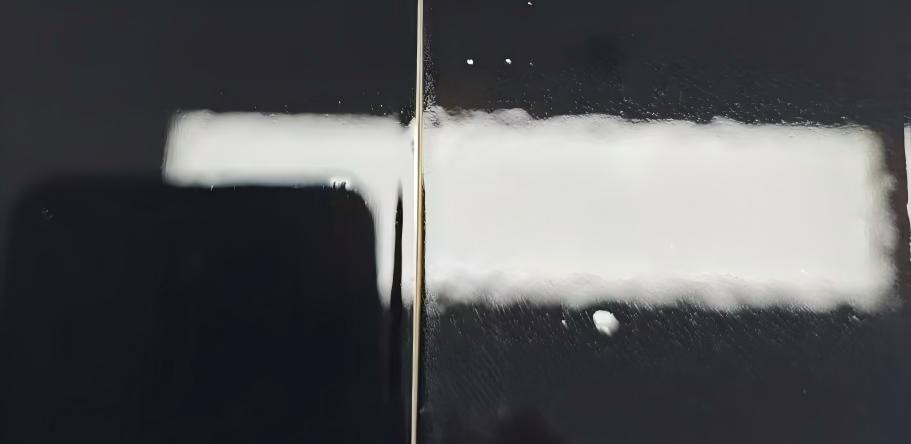

| Apariencia | Visual | Smooth and even | Many tiny bubbles | ||

| Apariencia |  | ||||

| Appearance under magnification |  | ||||

Experimental Conclusion

- The liquid coating of 2K PU Black (EEP) has a relatively lower odor; its flowability is slightly better; the flow-coated film thickness is lower, indicating better flowability; the gloss is slightly higher; the application performance is slightly better, allowing for a shorter standing time after spraying, resulting in a bubble-free film even at a higher thickness.

- 2K PU Black (EEP) and 2K PU Black (PMA) are identical in terms of drying time, appearance, hardness, and adhesion.

The above tests prove that the new solvent EEP demonstrates potential for broad application in areas such as automotive refinish paints, vehicle coatings, marine paints, general industrial paints, wood coatings, floor paints, and anti-corrosion paints.

For further details on PREC’s functional solvents, please visit: Disolvente PREC EEP