Shenzhen Prechem New Materials Co, Ltd.

Comparative Performance Testing of EEP vs. PMA in 2K Epoxy Coatings

Experimental Purpose and Conditions

Apply the new solvent EEP and the traditional solvent PMA respectively in a 2K epoxy paint system. Compare the performance differences generated by the two in the 2K epoxy paint system by analyzing the results of a series of performance tests.

Test Conditions: Temperature 25-27°C, Humidity 55-65%.

Test Basis: Reference to HG/T4566-2013 Epoxy Resin Primer Industry Standard.

Experiment Design and Data Analysis

Technical Parameters of Main Raw Materials:

| Name | Apparence | Point d'éclair | Purity | Point d'ébullition | Viscosity 25°C, mPa.s |

| EEP (Ethyl 3-Ethoxypropionate) | Colorless transparent | 59°C | ≥99% | 169°C | 1.3 |

| PMA (Propylene Glycol Monomethyl Ether Acetate) | Colorless transparent | 42°C | ≥99% | 145°C-146°C | 1.6-2.5 |

1. Clear Coat Preparation

Clear Coating Main Agent Formula:

| No. | Material | Dosage A1 | Dosage A2 | Supplier | Production Process |

| 1 | NPEF-170 Epoxy Resin | 50 | 50 | NAN YA | Add raw materials in sequence, disperse at medium speed 500 rpm for 10 minutes; |

| 2 | White Paste | 45 | 45 | Commercial | |

| 3 | EEP | 5 | – | PREC | |

| 4 | PMA | – | 5 | Commercial | |

| Total | 100 | 100 |

Paint Curing Agent B Formula:

| No. | Material | Dosage | Supplier |

| 1 | Polyamide Curing Agent | 50 | Commercial |

| 2 | Xylene | 35 | Commercial |

| 3 | n-Butanol | 15 | Commercial |

Diluent Formula:

| No. | Material | Dosage | Supplier |

| 1 | Xylene | 100 | Commercial |

2K EP (EEP) Ratio Main Agent A1: Curing Agent B: Diluent C = 100:100:15

2K EP (PMA) Ratio Main Agent A2: Curing Agent B: Diluent C = 100:100:15

2. System Test Results and Analysis

| No. | Test Items | Test Standards | Requirement | Test Results | |

| 2K EP (EEP) | 2K EP (PMA) | ||||

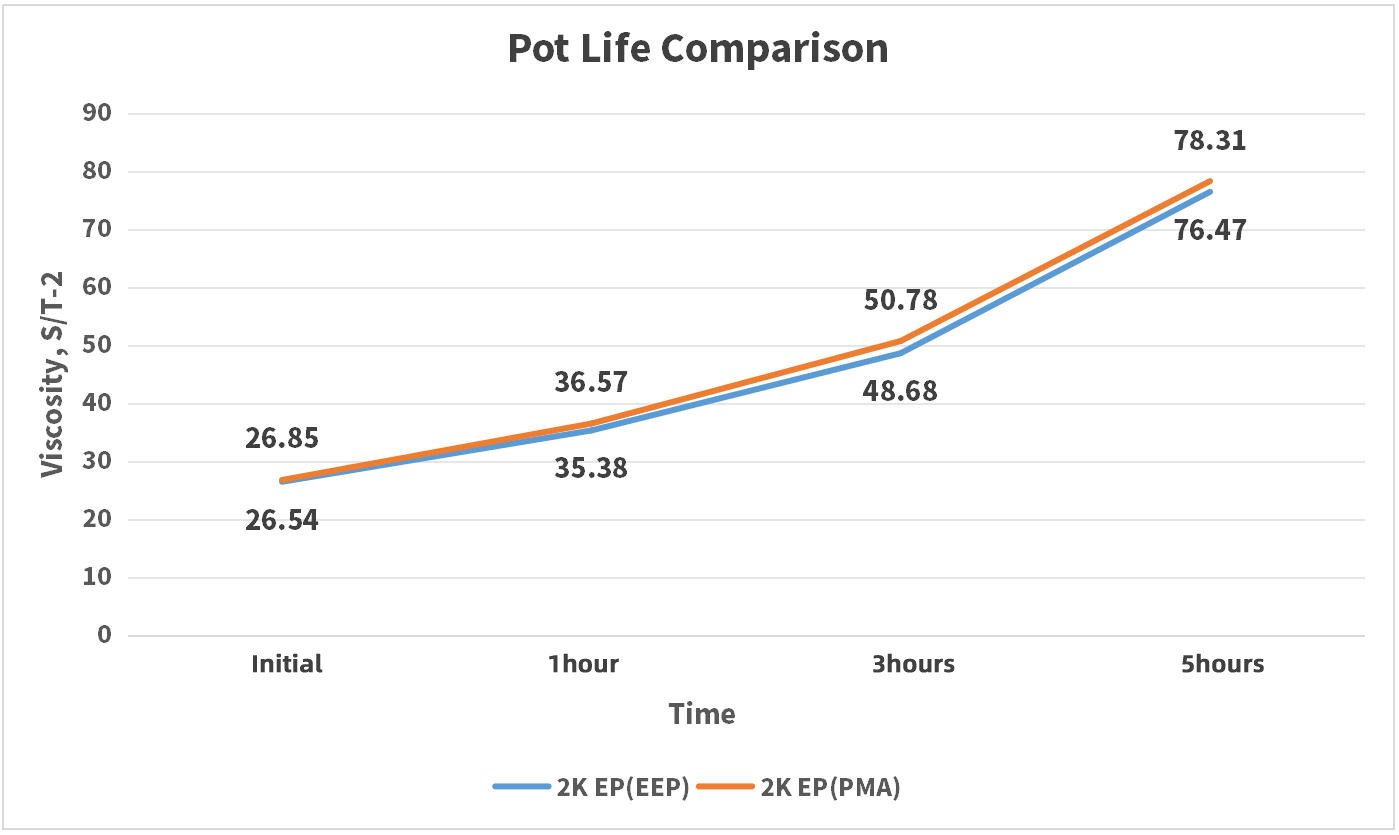

| 1 | Pot Life Viscosity (Clear Coating), S/T-2 | ||||

| Initial | – | Measured | 26.54 | 26.85 | |

| 1 hour | – | Measured | 35.38 | 36.57 | |

| 3 hours | – | Measured | 48.68 | 50.78 | |

| 5 hours | – | Measured | 76.47 | 78.31 | |

| |||||

| Pot Life Adhesion, grade (Tinplate sanded) | |||||

| Initial | – | ≤1 | 1 | 1 | |

| 1 hour | – | ≤1 | 1 | 1 | |

| 3 hours | – | ≤1 | 1 | 1 | |

| 5 hours | – | ≤1 | 2 | 2 | |

| 2 | Clear Coating Viscosity, mPa.s@25.5°C | GB/T 2794-2013 | Measured | 784.79 | 849.93 |

| 3 | Drying Time | ||||

| Touch Dry, h | GB/T 1728-1979 | ≤4 | 2 | 2 | |

| Hard Dry, h | GB/T 1728-1979 | ≤24 | 20 | 20 | |

| 4 | Film Appearance | – | Normal | Normal | Normal |

| 5 | Thickness (Flow Coating), μm | – | Measured | 60.3 | 65.6 |

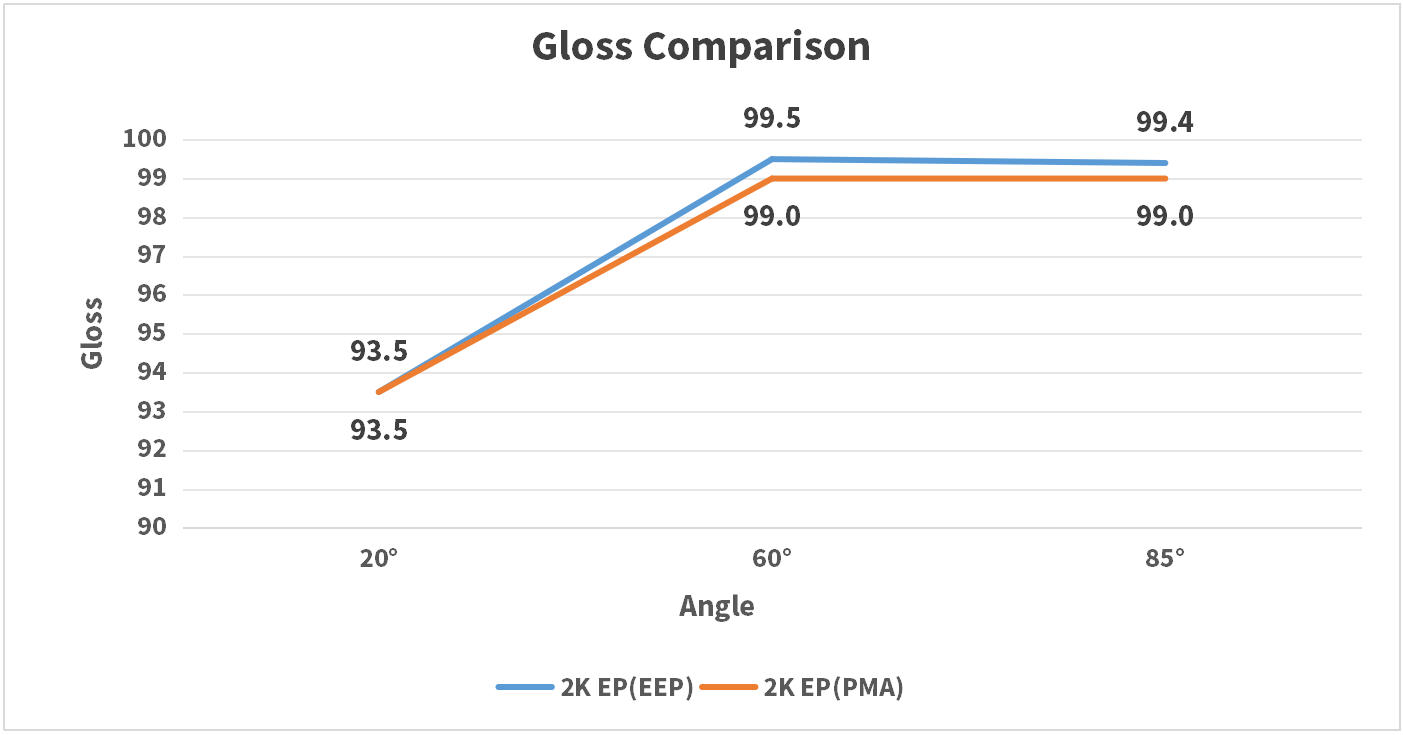

| 6 | Gloss at 20°/60°/85° | GB/T 9754-2007 | Measured | 93.5/99.5/99.4 | 93.5/99.0/99.0 |

| |||||

| 7 | Pencil Hardness (Scratch – Zhonghua) | GB/T 6739-2006 | Measured | H | H |

| 8 | Cross-Cut Test, grade | GB/T 9286-1998 | ≤1 | 1 | 1 |

| 9 | Impact Resistance, cm | GB/T 1732-1993 | 50 | No cracking | No cracking |

Experimental Conclusion

Through the comparison of data from the series of tests, it was found that:

- The viscosity of the EEP group during pot life is slightly lower than that of the PMA group, indicating that 2K EP (EEP) has a slightly better viscosity reduction effect; the gloss angle data shows that 2K EP (EEP) has slightly higher gloss.

- The adhesion, hardness, drying time, impact resistance, and other properties of 2K EP (EEP) and 2K EP (PMA) are the same. These results indicate that EEP holds significant potential for application in various fields, including automotive coatings, marine paints, structural steel coatings, industrial finishes, floor coatings, anticorrosive paints, adhesives, and electronic materials.

For further details on PREC’s functional solvents, please visit: Solvant PREC EEP