Shenzhen Prechem New Materials Co., Ltd.

APE Monomer

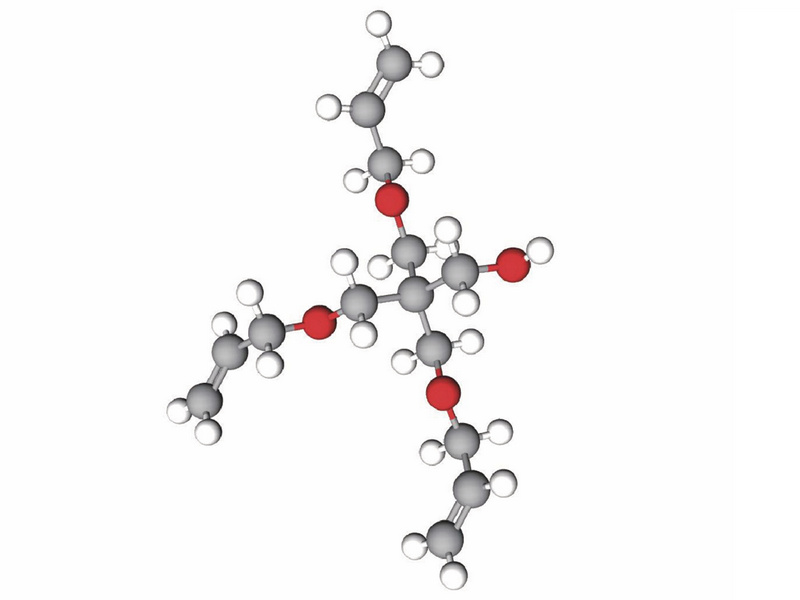

Pentaerythritol Triallyl Ether

Description

APE (Pentaerythritol Triallyl Ether) is a specialty monomer with four active functional groups in the molecule, including three allyl groups and one hydroxyl group. It is extensively used in the paint, coating, and synthetic resin industries as a polymer monomer or cross-linking agent. APE helps improve product quality, water absorption, and other properties, providing a reliable solution to variable applications.