Shenzhen Prechem New Materials Co., Ltd.

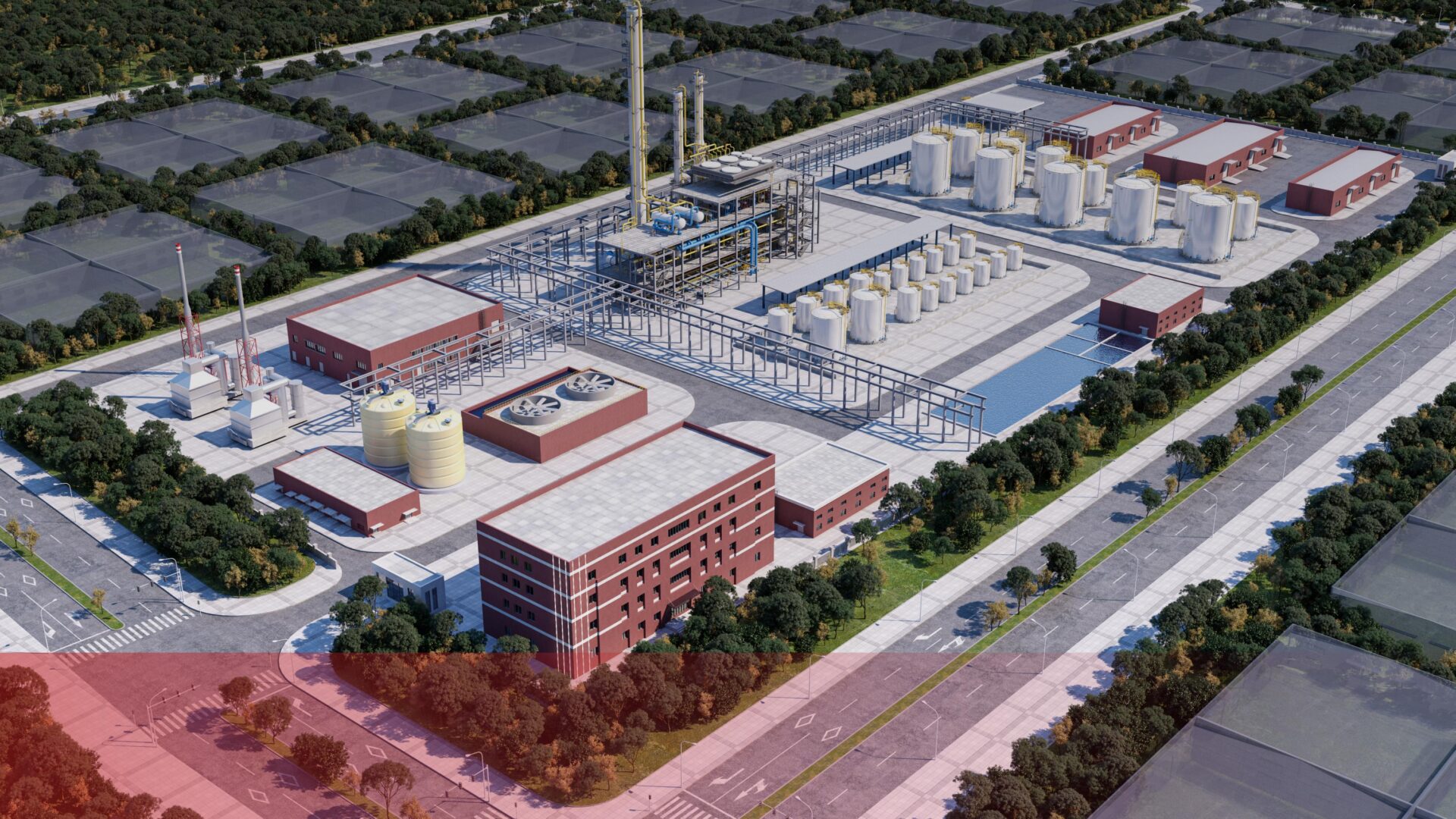

PREC Huaibei Plant’s EIA Approval Sets Green Manufacturing Benchmark in Anhui

Huaibei, Anhui Province, China, February 6, 2025 — The HuaiBei Municipal Ecology and Environment Bureau has approved the Environmental Impact Assessment (EIA) for Anhui Prechem New Materials Co., Ltd.’s “Annual Production of 30,000 Tons of EEP/MMP Solvents and Supporting 30,000 Tons of EA/MA Monomers Project” (Approval No.: Huai Huan Xing [2025] 04). This milestone underscores the project’s compliance with China’s stringent environmental standards and its alignment with green manufacturing principles. With a total investment of CNY 202.96 million, the facility represents a strategic expansion by Shenzhen Prechem New Materials Co., Ltd. in East China.

Project Overview

Located at No. 8 Huaixing South Road, HuaiBei New Coal Chemical Industry Park, the 75-mu (approximately. 5 hectares) facility will produce high-performance solvents, including 3-ethoxypropionic acid ethyl ester (EEP) and 3-methoxypropionic acid methyl ester (MMP), with over 30% designated for electronic-grade applications. The project also includes supporting production lines for ethyl acrylate (EA) and methyl acrylate (MA) monomers. Upon completion, the plant will deliver an annual output of 30,000 tons of functional solvents and 30,000 tons of monomers, catering to industries such as semiconductors and advanced coatings.

With a total investment of CNY 202.96 million, the project has been recognized by the HuaiBei Ecology and Environment Bureau as compliant with national industrial policies and local development plans. The bureau affirmed that its pollution control measures “ensure standard-compliant emissions and controllable environmental risks,” underscoring the company’s dedication to environmental responsibility.

Eco-Technical Framework

PREC (Anhui) has implemented a multi-layered environmental management system covering exhaust gases, wastewater, solid waste, and noise:

1. Exhaust Gas Treatment: High-Efficiency Purification and Resource Recovery

- Organized emissions: Industrial exhaust from production units, waste liquid incinerator flue gas, dust from material handling, hazardous waste storage, wastewater treatment facilities, and laboratory emissions are collected, treated, and discharged in compliance with standards (GB31571-2015, DB34/4812.3-2024, GB14554-93, and GB18484-2020).

- Fugitive emissions: Enhanced equipment sealing and strict negative pressure controls minimize methanol and volatile organic compound (VOC) emissions, meeting national standards (GB16297-1996 and GB37822-2019).

2. Wastewater Management: Categorized Treatment and Zero Discharge

A dual drainage system separates rainwater and sewage. Process wastewater from solvent/monomer production, equipment cleaning, floor washing, initial rainwater, and other sources undergoes onsite treatment before being discharged into the municipal pipeline for further processing at the HuaiBei New Coal Chemical Industrial Park’s centralized wastewater plant.

3. Solid Waste Handling: Regulatory Compliance

- General waste (packaging materials, bio-sludge, dust) is recycled.

- Hazardous waste (spent catalysts, chemical-contaminated packaging, waste lubricants, activated carbon, incineration residues) is stored in dedicated facilities and disposed via licensed contractors.

- Household waste is managed by municipal sanitation services.

- Storage and transfer processes adhere to GB18599-2020 and GB18597-2023 standards to prevent secondary pollution.

Social Responsibility

Aligned with its parent company’s “technology-driven, eco-first” philosophy, PREC (Anhui) has pledged transparency in environmental data disclosure and regular sustainability reporting. The project utilizes clean energy and optimized processes to cap annual emissions at:

- Sulfur dioxide (SO₂): 0.871 tons

- Nitrogen oxides (NOx): 2.442 tons

- Particulates: 0.534 tons

- Non-methane hydrocarbons (NMHC): 2.44 tons

These levels comply with HuaiBei’s pollutant cap requirements.

Industry Impact

Amid tightening environmental regulations, the project’s approval sets a precedent for eco-compliance in the chemical industry. Notably, the bureau highlighted “no public opposition” during the review, reflecting constructive engagement with local communities and regulators.

PREC (Anhui) has committed to implementing the “three simultaneities” principle (simultaneous design, construction, and operation of pollution control measures) to ensure ongoing compliance. Leveraging HuaiBei’s coal-chemical industrial ecosystem, the facility aims to become a model for green manufacturing and high-performance materials production.