Shenzhen Prechem New Materials Co., Ltd.

Environmentally Friendly MMP as a Replacement for PMA (Part 1): Evaporation Rate Comparison

Experimental Design

This study evaluated the evaporation rates of MMP and PMA under three scenarios: pure solvents, blended solvents, and blended solvents with nitrocellulose. The experiments validated MMP’s superior performance in coating applications. Key physicochemical properties are compared below:

| Physicochemical Properties | MMP | PMA | BA |

| Molecular Formula | C₅H₁₀O₃ | C₆H₁₂O₃ | C6H12O₂ |

| Molecular Weight | 118.13 | 132.16 | 116.16 |

| CAS No. | 3852-09-3 | 108-65-6 | 123-86-4 |

| Density (g/cm³) | 1.010 | 0.96 | 0.88 |

| Appearance | Colorless Transparent Liquid | Colorless Transparent Liquid | Colorless Transparent Liquid |

| Purity (%) | ≥99 | ≥99 | ≥99 |

| Flash Point (°C, closed cup) | 47 | 47.9 | 22.2 |

| Boiling Point (°C) | 140-148 | 154.8 | 126.1 |

| Refractive Index | 1.4005-1.4040 | 1.401-1.403 | 1.398 |

Data Analysis

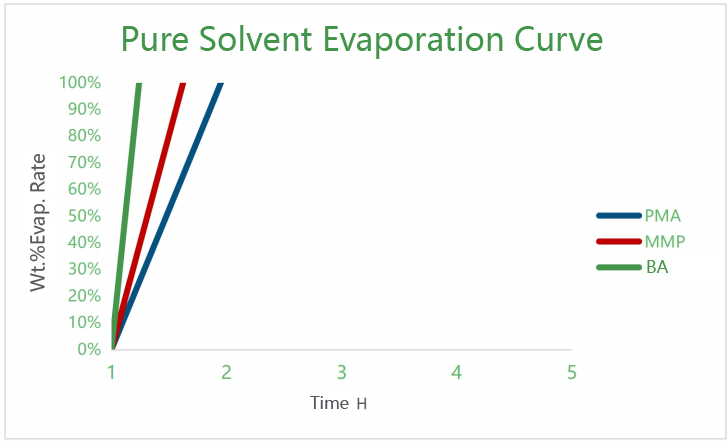

1. Pure Solvent Test

- Three glass vials containing equal masses of MMP, PMA, and BA were placed outdoors under sunlight.

- Periodic weight measurements were taken to calculate volatility rates.

- As shown in Figure 1, MMP and PMA displayed nearly identical volatility curves.

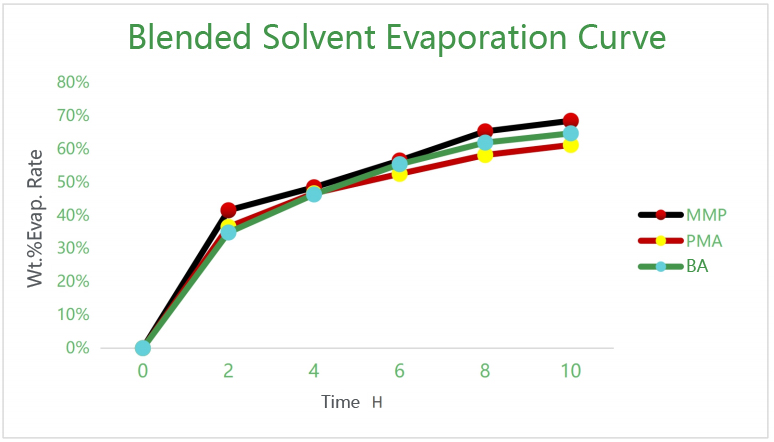

2. Blended Solvent Test

- Three vials were prepared with the following composition: Ethyl acetate (15%), isopropyl alcohol (10%), butyl acetate (15%), cyclohexanone (10%), toluene (35%), and MMP/PMA/BA (15%).

- The samples were exposed to sunlight, and weight loss was monitored.

- Figure 2 confirms that MMP and PMA exhibit comparable volatility rates in blended solvent systems.

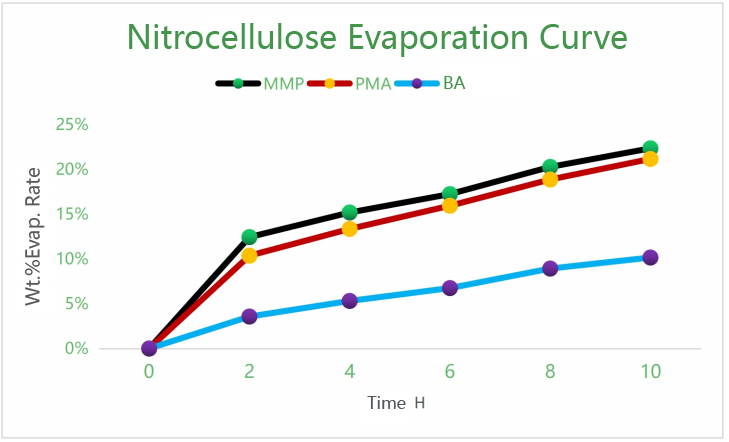

3. Blended Solvent + Nitrocellulose Test

- The above blended solvents were mixed with nitrocellulose at a 1:1 ratio, dissolved under agitation, and exposed to sunlight.

- Weight measurements revealed similar volatility rates for MMP and PMA in this matrix, as illustrated in Figure 3.

Experimental Conclusions

The evaporation rates of methyl 3-methoxypropionate (MMP) and propylene glycol methyl ether acetate (PMA) were tested using butyl acetate (BA) as a reference benchmark. Experimental data demonstrate that MMP and PMA exhibit comparable evaporation rates both in pure solvent form and within blended diluent systems. This indicates that MMP possesses similar evaporation characteristics to PMA in paint and coating applications, supporting its potential as a sustainable substitute for PMA in these industries.

Background

Solvents play a critical role in coatings and inks by dissolving resins, pigments, and active ingredients, facilitating application and transport. However, solvent evaporation during film formation releases volatile organic compounds (VOCs), contributing to environmental pollution. Global regulations increasingly restrict VOC emissions, driving demand for solvents with enhanced dissolution efficiency, lower toxicity, and reduced environmental impact.

Oxygenated solvents like glycol ethers and esters combine the dissolution properties of ethers and alcohols/esters, offering broader applicability. PMA, a widely used ether-ester solvent, exemplifies this category. Recent advancements have identified methyl 3-methoxypropionate (MMP) as a superior, sustainable alternative to PMA.

For more information about functional solvents, please visit: PREC MMP Solvent.