Shenzhen Prechem New Materials Co., Ltd.

Comparative Application of EEP, MMP, and PMA in Polyaspartic Polyurea Resin Systems (Part 2)

Experimental Objective

To compare the solubility of novel solvents EEP and MMP versus the traditional solvent PMA in blended solvent systems for polyaspartic polyurea coatings, and to evaluate the effect of EEP and MMP on the appearance of the paint film.

Experimental Data Analysis

Test 1: Solubility Test of Blended Solvents on Polyaspartic Polyurea Coatings

1.1 Preparation of 90% High Solid Content Polyaspartic Polyurea Coating

EEP and MMP were incorporated into blended solvent systems and used to prepare a 90% high solid content polyaspartic polyurea coating (Component A).

| 90% High Solid Content Polyaspartic Polyurea Coating Formulation | Ratio | Formulation 1-PMA | Formulation 2-EEP | Formulation 3-MMP |

| F520 | 20.00 | F520 | F520 | F520 |

| F420 | 20.00 | F420 | F420 | F420 |

| A3202 | 1.00 | A3202 | A3202 | A3202 |

| A3411 | 0.40 | A3411 | A3411 | A3411 |

| 1503L Molecular Sieve | 4.00 | 1503L Molecular Sieve | 1503L Molecular Sieve | 1503L Molecular Sieve |

| R-606 Titanium Dioxide | 45.00 | R-606 Titanium Dioxide | R-606 Titanium Dioxide | R-606 Titanium Dioxide |

| A3303 | 0.20 | A3303 | A3303 | A3303 |

| A3410 | 0.10 | A3410 | A3410 | A3410 |

| A3101 | 0.10 | A3101 | A3101 | A3101 |

| A3507 | 1.00 | A3507 | A3507 | A3507 |

| FW200 Black Paste | 0.30 | FW200 Black Paste | FW200 Black Paste | FW200 Black Paste |

| Solvent Sample (Pre-grinding) [INDUSTRIAL] | 1.69 | PMA | EEP | MMP |

| Industrial n-Butyl Acetate (Post-grinding) | 2.37 | n-Butyl Acetate | n-Butyl Acetate | n-Butyl Acetate |

| Xylene (Post-grinding) | 2.37 | Xylene | Xylene | Xylene |

| Solvent Sample (Post-grinding) [INDUSTRIAL] | 1.47 | PMA | EEP | MMP |

| SUM | 100.00 | |||

| Notes: 1. Requires grinding with a three-roll mill, 30 min/time, grind 3 times, cooling with tap water between intervals; 2. During solvent batching, only add 20.3g of PMA/EEP/MMP solvent initially, add the rest after viscosity measurement. | ||||

Table 1: 90% High Solid Content Polyaspartic Polyurea Coating (Component A)

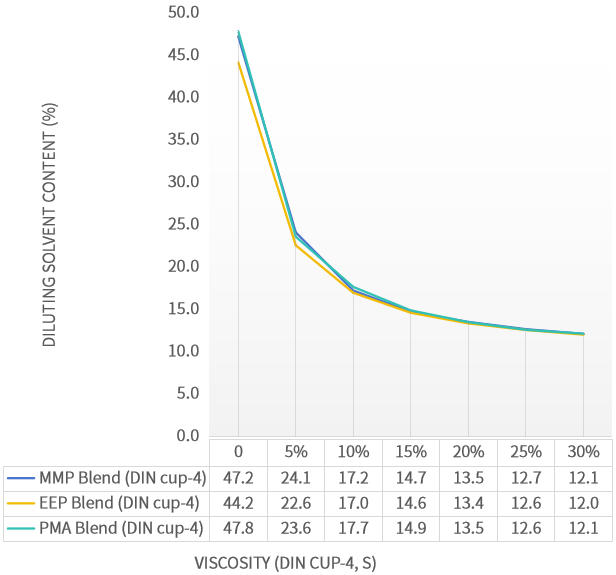

1.2 Viscosity Change Curves Measurement

Blended solvents of EEP, MMP, and PMA were used to dissolve the polyaspartic polyurea coating (Component A) at proportions of 5%, 10%, 15%, 20%, 25%, and 30%. Viscosity change curves were measured to analyze the solubility of the blended solvents for the polyaspartic polyurea coating. (Note: Since the evaluation system is paint, viscosity was measured using Cup-4 viscosity at 24°C–25°C.)

1.3 Experimental Summary

- The blended solvent of the novel solvent EEP exhibits slightly better solubility for polyaspartic polyurea coatings than the traditional solvent PMA.

- The blended solvent of the novel solvent MMP shows solubility for polyaspartic polyurea coatings very close to that of the traditional solvent PMA.

Test 2: Evaluation of the Effect of EEP and MMP on Paint Film Appearance

The blended solvents of the novel solvents were incorporated into the formulation of a 90% high solid content polyaspartic polyurea anti-corrosion coating. The coating was diluted to application viscosity and sprayed onto panels. A comparison was made with the blended solvent of the traditional solvent PMA, controlling paint parameters to evaluate and compare the paint film appearance.

| Test Item / Category | Formulation 1-PMA | Formulation 2-EEP | Formulation 3-MMP |

| State in Container (within 72h) | Uniform | Uniform | Uniform |

| Fineness≤30μm | 30.0 | 25.0 | 30- |

| (Cup-4) Viscosity / s | 46 | 44 | 46 |

| (Rotational) Viscosity / cps | 371.2 | 328.7 | 410.5 |

| Solid Content≥ 90.0% | 90.7 | 90.4 | 90.5 |

| Sagging / μm | 75 | 75 | 75 |

| State in Container (after 10 days) | Uniform, sandy powder | Gel-like deposition, sandy powder | Uniform, sandy powder |

| Pot Life / min | 35 | 45 | 40 |

| 20-26μm Surface Dry Time / min | 32 | 30 | 30 |

| 20-26μm Dry Time / min | 107 | 105 | 101 |

| Film Appearance | Pronounced orange peel with minor pinholes. | Slight orange peel with minor pinholes. (Significantly superior to PMA) | Orange peel with minor pinholes. (Inferior to PMA) |

| 20-26μm Pencil Hardness | HB | HB | HB |

| 20-26μm Flexibility/Folding | 1mm | 1mm | 1mm |

| 20-26μm Impact Resistance / cm | 50 | 50 | 50 |

| 20-26μm Adhesion (Cross-cut) | Grade 1 (21μm) | Grade 1 (19μm) | Grade 2 (27μm) |

| 40-50μm Gloss (60° / unit) | 91.3 | 91.9 | 90.4 |

Table 2: Performance Comparison Data of Novel Solvents in 90% High Solid Content Polyaspartic Polyurea Coating System

As can be seen from Table 2:

- EEP shows a significant advantage in reducing orange peel defects.

- Both EEP and MMP exhibit varying degrees of extension in pot life.

- The paint system formulated with EEP has relatively weaker stability under the same conditions (related to solubility).

Note: Since the purpose of this experiment is to study the solubility of the novel solvents, properties such as flexibility, impact resistance, adhesion, and gloss were only routinely tested and not compared in depth.

Series of Experiments Summary

- Whether in single solvent or blended solvent systems, the EEP and MMP exhibit slightly better solubility for polyaspartic polyurea resin than the traditional solvent PMA.

- For MMP, EEP, and PMA, their blended solvent systems show better solubility for polyaspartic polyurea resin than their respective single solvents.

- The blended solvent of EEP exhibits slightly better solubility for polyaspartic polyurea coatings than the traditional solvent PMA; the blended solvent of MMP shows solubility very close to that of the traditional solvent PMA.

- Through performance comparison data in the 90% high solid content polyaspartic polyurea coating system, it was found that EEP has significant advantages in reducing orange peel defects; both EEP and MMP exhibit varying degrees of extension in pot life.

For further details on PREC’s functional solvents, please visit: PREC EEP Solvent and PREC MMP Solvent.